The Most Overlooked ROI Opportunity in Fleet Tech: Video Data for Preventive Maintenance

Picture this: Your star driver calls in at 6 AM from the side of I-75. The transmission just seized up on your newest delivery truck, the one that passed its last inspection with flying colors just three weeks ago. Now you're looking at $8,000 in repairs, a day of lost revenue, and a frustrated customer whose shipment won't arrive on time.

What if I told you that your fleet's cameras could have spotted the warning signs of that transmission failure two weeks before it happened?

Most fleet managers think of video systems as accident investigators, tools that help you piece together what went wrong after disaster strikes. But you're missing the biggest ROI opportunity sitting right in your dashboard: using video data to prevent costly breakdowns before they happen.

The Hidden Costs of Reactive Maintenance Are Crushing Your Bottom Line

Your fleet faces an enormous challenge that traditional telematics can't solve. While your GPS tracking tells you where your vehicles are and your engine diagnostics report basic performance metrics, neither system can see what's actually happening to your equipment in real-time.

Every day, your vehicles experience wear patterns, fluid leaks, tire degradation, and component stress that develops gradually, long before diagnostic codes trigger alerts. By the time your traditional monitoring systems detect a problem, you're already facing emergency repairs that cost 3-5 times more than preventive fixes.

Consider these sobering statistics: Unplanned downtime costs fleets an average of $448-760 per day per vehicle. Emergency roadside repairs run $2,000-5,000 more expensive than scheduled maintenance. Most devastating of all, 40% of vehicle breakdowns show visible warning signs for weeks before complete failure occurs.

Your current approach leaves massive gaps in vehicle health monitoring, and those gaps are definitely costing you money every single month.

Video Data Reveals What Sensors Can't Detect

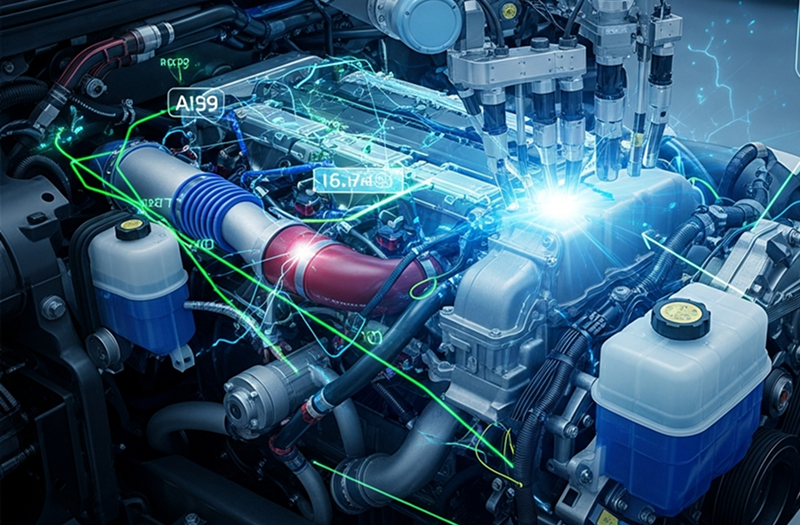

Here's where video technology transforms from a safety tool into your most powerful predictive maintenance weapon. Modern AI-powered cameras don't just record incidents, they continuously monitor your vehicles' physical condition in ways that traditional sensors simply cannot match.

Your multi-camera system captures visual evidence of developing maintenance issues that would otherwise go unnoticed until catastrophic failure occurs. Fluid leaks creating stains under parked vehicles, tire wear patterns indicating alignment problems, exhaust smoke changes suggesting engine trouble, brake component degradation, hydraulic system stress indicators, all visible to trained eyes (or AI systems) reviewing video data.

Unlike diagnostic codes that only trigger after problems reach critical thresholds, video monitoring catches issues during their early development stages when fixes cost hundreds instead of thousands.

Think about your last major repair bill. Could visual inspection have spotted the problem earlier? In most cases, the answer is definitively yes.

Real-Time Visual Inspection Delivers Massive Cost Savings

Smart fleet managers are already leveraging video data for preventive maintenance, and the results speak volumes about this overlooked opportunity. Real-time visual monitoring allows you to identify maintenance needs during regular operations instead of waiting for scheduled inspections or emergency breakdowns.

Your cameras can detect brake pad wear by monitoring wheel dust patterns, catch transmission problems through visual exhaust analysis, spot cooling system issues via steam or leak detection, and identify suspension problems by analyzing vehicle stance and load distribution.

The enormous benefit becomes clear when you calculate the math: Preventing just one major breakdown per vehicle annually saves $3,000-8,000 in emergency repair costs, not counting the additional savings from avoided downtime, towing fees, and customer satisfaction issues.

Video-based preventive maintenance programs typically show 400-600% ROI within the first year of implementation, primarily through breakdown prevention and optimized maintenance scheduling.

Multi-Camera Systems Provide Complete Vehicle Health Visibility

Single-camera installations miss critical maintenance indicators that develop in areas outside their limited field of view. Your fleet deserves comprehensive visual monitoring that captures every angle where problems typically develop.

Multi-camera configurations monitor engine compartments, undercarriage areas, cargo spaces, and external components simultaneously. This complete coverage ensures that developing issues get detected regardless of where they originate on your vehicles.

External cameras track tire condition, body damage progression, and load-related stress indicators. Interior cameras monitor dashboard warning lights, gauge readings, and operator compartment conditions. Undercarriage cameras catch the fluid leaks, exhaust problems, and suspension issues that often go unnoticed until they cause expensive failures.

Your investment in comprehensive video coverage pays for itself through early problem detection and strategic maintenance scheduling that prevents disastrous situations.

AI-Powered Analysis Takes Visual Inspection to the Next Level

Manual video review for maintenance purposes presents practical challenges that limit its effectiveness in busy fleet operations. You need automated analysis that continuously monitors your footage and alerts you to developing problems without requiring constant human oversight.

Advanced AI systems learn to recognize normal vs. abnormal visual patterns in your fleet's operation. These systems flag unusual smoke patterns, detect fluid accumulations, monitor component wear indicators, and track changes in vehicle performance characteristics over time.

The technology integrates seamlessly with your existing fleet management platform, delivering maintenance alerts alongside your current safety and compliance notifications. You get early warning systems that help you schedule preventive repairs during convenient maintenance windows instead of dealing with emergency breakdowns.

Don't settle for reactive maintenance strategies when proactive video monitoring can dramatically reduce your repair costs and vehicle downtime.

Integration With Existing Fleet Management Creates Unified Operations

Your video-based maintenance monitoring works most effectively when integrated with your current fleet management systems. This unified approach combines visual inspection data with telematics, GPS tracking, and traditional diagnostics to provide complete vehicle health visibility.

Centralized dashboards display maintenance alerts alongside safety notifications, route optimization, and driver performance metrics. Your maintenance team receives visual evidence supporting their repair decisions, while your operations team gets accurate timelines for vehicle availability.

The integration eliminates data silos that often prevent fleet managers from making informed maintenance decisions. You can correlate visual maintenance indicators with performance metrics, driver feedback, and historical repair patterns to optimize your entire maintenance strategy.

Imagine having complete visibility into your fleet's health status from any device, anywhere, at any time. That level of operational control delivers measurable improvements in vehicle reliability and cost management.

The ROI Math That Changes Everything

Let's examine the concrete financial impact of video-based preventive maintenance monitoring. Your typical fleet vehicle faces $4,000-6,000 in annual maintenance costs, with emergency repairs accounting for 60-70% of total expenses.

Video monitoring systems that prevent just two major breakdowns per vehicle annually generate $6,000-16,000 in direct savings. Add the indirect benefits: reduced downtime, improved customer satisfaction, lower insurance premiums, extended vehicle life: and your total ROI easily exceeds 500%.

The technology investment typically pays for itself within 6-8 months through breakdown prevention alone. Every month afterward represents pure profit improvement through optimized maintenance operations.

We can see similar results across diverse fleet applications: delivery companies reducing transmission failures by 65%, construction fleets cutting hydraulic system breakdowns by 50%, and transport operations eliminating 80% of roadside emergency calls.

Your Fleet's Competitive Advantage Starts With Better Visibility

Forward-thinking fleet managers understand that operational efficiency depends on proactive maintenance strategies. While your competitors deal with unexpected breakdowns and emergency repair costs, you'll maintain reliable operations through early problem detection and strategic maintenance scheduling.

Video-based preventive maintenance represents a significant competitive advantage that improves your service reliability, reduces operating costs, and enhances your reputation for dependable operations. Your customers notice when deliveries arrive on time consistently, and your drivers appreciate working with well-maintained equipment.

The technology also supports your safety and compliance objectives while delivering these maintenance benefits. You're not adding complexity to your operations: you're maximizing the value of systems you likely already have or plan to install.

Don't let this overlooked ROI opportunity continue costing your fleet thousands in preventable maintenance expenses.

Transform Your Maintenance Strategy Today

The most successful fleets combine traditional diagnostics with visual monitoring to create comprehensive vehicle health management systems. Your operation deserves the same level of preventive maintenance capability that's already helping smart fleet managers reduce costs and improve reliability.

Ready to discover how video data can transform your maintenance operations and deliver massive cost savings? Eyeride's multi-camera fleet management platform provides the complete visual monitoring solution your fleet needs to prevent expensive breakdowns and optimize maintenance scheduling.

Schedule your personalized demo today and see how unlimited cloud recording and AI-powered analysis can revolutionize your fleet's maintenance strategy. Call 833-EYERIDE (833-393-7433) or visit eyeride.io to start reducing your maintenance costs immediately.